Change Language :

Reduce your tech up & costs now with drylin® lead screw technology

Determine your personal savings potential NOW

Whether in monetary terms or as time savings in assembly, selection, design, etc. Technical improvement in the form of ease of installation, durability, etc. If we cannot name any savings or technical improvements, we will recommend an alternative solution.

Always the most favourable thread system that works.

With drylin® screw drives from igus®.

Overengineering is a thing of the past. The best thread system does not have to be the most expensive.

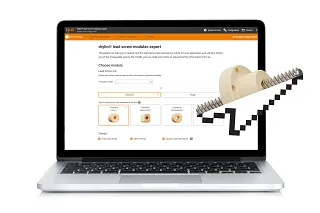

Determine the screw drive with the best price-performance ratio for your application in no time at all.

Configure your lead screw quickly and easily online. You can also receive a free drawing, CAD data or live price information.

Quick and easy online calculation

Find out in just a few minutes how long our plastic-lead screw nuts will last in your application - and then select the thread system with the best price-performance ratio. Customised for your application.

Tech up

Save 100 % lubricant

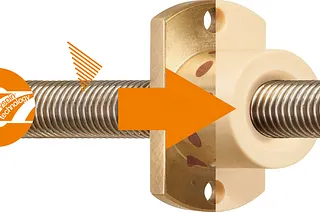

Lubrication is essential for metal lead screw nuts, otherwise they will rust quickly and become deformed during use. With our drylin® plastic lead screw nuts, you don't need a single drop of lubricant. As a result, our lead screw technology scores highly in terms of smooth running, as they do not have to overcome the resistance of the lubricant and start up with a significantly lower breakaway torque.

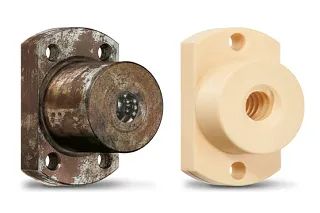

Corrosion? No thanks!

lead screw nuts made of plastic have a decisive advantage over those made of metal: they are 100 % rustproof. Even when used in corrosive environments, drylin® lead screws always maintain their smooth running and long service life - and are completely maintenance-free.

Save up to 88 % weight

Metal lead screw nuts are robust - and heavy. drylin® plastic lead screw nuts offer the perfect alternative for a wide range of applications because they are light, reliable and durable. drylin® lead screws are frequently used in the automotive industry and railway technology. Wherever low weight is important, our lightweight plastic lead screw nuts are ideal.

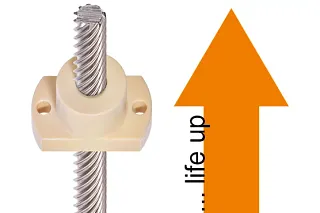

Up to 30 % longer service life

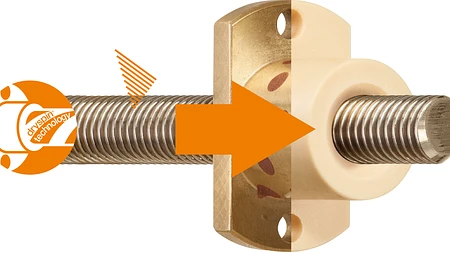

The dryspin® technology developed by us achieves up to 30 % longer service life due to the asymmetry of the threads and increased efficiency thanks to the flat flank angle. The contact surface between the threaded spindle and the lead screw nut is reduced and the threaded systems run almost silently and vibration-free under load.

Cost down

Up to 50.9 % cheaper than comparable metal solutions

Our plastic lead screw nuts not only stand out from their metal counterparts thanks to technical advantages such as freedom from lubricants and corrosion, but are also up to around 50 % cheaper.

Do you need further cost comparisons for your metal or plastic thread systems in order to identify your savings potential? We will be happy to advise you. It's our job!

Proven in more than 50 industries

3D printers | vending machinery | railway technology | construction machinery | facade technology | fluid technology |

| beverage industry | wood industry | camera technology | Food industry | Medical technology | Model making |

| furniture & Industrial Design | robots | solar technology | textile industry | packaging industry | and much more.

Sustainability

Tech up. Cost down. Change now!

Reduce your tech up & costs with other igus® products

Consulting

I look forward to answering your questions

Conlog LTD (Stocking Distributor)+972 3 9269595Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr